We all face the same danger: “If things stay as they are, Japanese food culture will soon decline.”

This reflects deep structural fatigue in the food business—staff shortages, uncertain procurement and prep forecasts, and razor-thin margins—that has reached its limit.

The issue is not simply IT or AI, but building new mechanisms that let people on the ground decide and act.

We will free the industry from its worn-out framework and create a new food economy where true value reaches those who need it,

implementing it directly from the front line.

We have refined this model through operating more than 16 restaurants in Canada and Japan,

and now we will redesign the old structure and cultivate it as the next infrastructure for Japan’s food future.

Mismatched supply driven by hidden demand, excessive intermediary margins, and a race to the bottom on price—

along with operations that rely too heavily on site-specific intuition—are problems we have long ignored.

These issues squeeze livelihoods, profitability, and even Japan’s culinary culture.

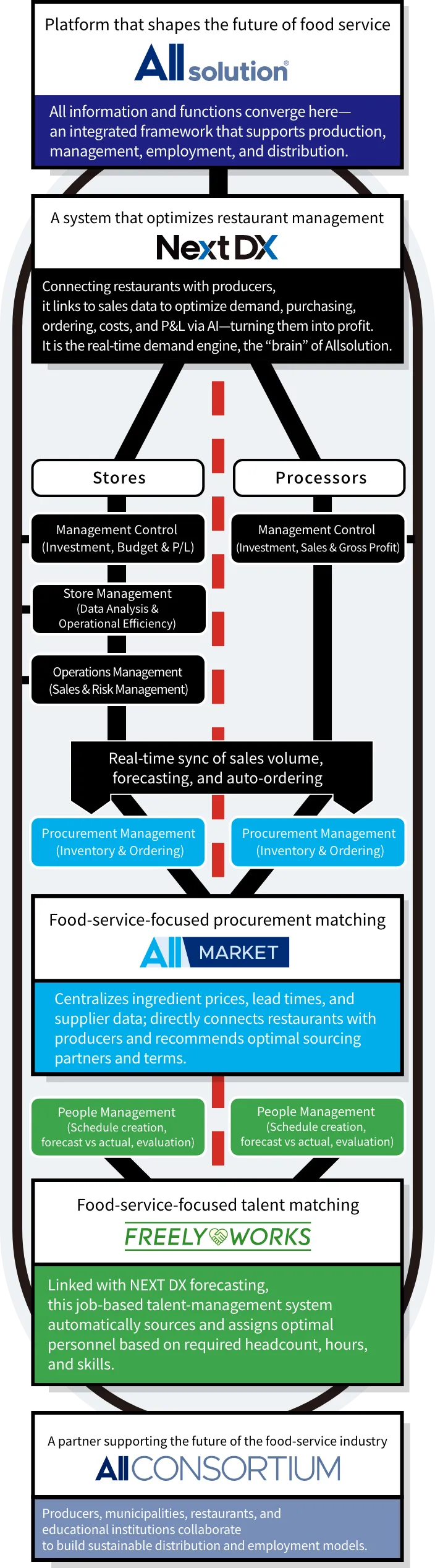

“All solution” increases transparency among every player—producers, logistics, restaurants, owners, staff, municipalities, and local communities—

rebuilding food infrastructure through a “Supply Web” that connects them as a plane, not isolated points,

generating healthier cycles of value and profit.

Where, what, and how must we change to rebuild food-service operations into workplaces that can truly endure?

Because Allsolution was born on the front line, it delivers direct solutions and transformation to every challenge.

For owners, managers, staff, chefs, floor managers, part-timers, etc.

We’re so busy that ordering always gets pushed back!

Purchasing is driven too much by gut feel; inventory control is a mess.

Next DX tracks sales and consumption in real time and auto-orders from producers based on forecasts, cutting manual order work, preventing over/under-stock, and relieving decision stress on-site.

Chasing cheap ingredients leaves us unhappy with quality and freshness!

Aren’t middle-man fees way too high? Good ingredients are unaffordable!

Next DX connects straight to producers, buying exact volumes at the right time, bypassing intermediaries to lower cost and supply top-grade ingredients reliably.

New or part-time staff often make prep mistakes.

Processing delivered ingredients takes far too much time and effort!

Producers process items to spec so they arrive ready to cook; sorting and prep time drops dramatically and workflows are standardized.

We estimated today’s rush—staff are nowhere near enough.

Kitchen is over-staffed today—who made this schedule?

Forecast data from Next DX syncs with Freely Works to auto-match required skills and headcount, flexibly securing “the right person for this task at this time” through job-based hiring.

Production, processing, retail, logistics, warehousing, part-time staff, etc.

Order notices always come late; we can’t prepare or schedule staff.

We never know shipment volume—how much stock should we keep?

NEXT DX shows downstream consumption in real time and creates an auto-order flow from stores, cutting overstock, waste, order errors, and workload.

Intermediary fees are way too high; we can’t make a profit.

We’re beaten down on price, yet quality still costs money—what gives?

Producers set fair prices and trade directly with stores; delivering only needed volumes slashes fees and logistics costs so product value flows straight into price.

We’re confident in quality, but don’t know how to sell it.

Stores need specific processing; we can do many things.

In partnership with the All team we propose use-specific processing and product development, co-creating branding—from presentation to storytelling—to turn “just another ingredient” into a chosen product.

We can’t gather enough hands for shipping or processing.

We don’t need lots of people; we need the right skills and headcount.

Linked with Freely Works, the talent system auto-matches needed people by task, timing, and skill; job-based assignments for “processing” and “shipping” optimize labor cost and keep operations flexible.

Not only restaurants and suppliers but also municipalities, retailers, schools, financial institutions, and local residents share the will to “support the future of food.” Their collaboration is what drives All solution. To make those ties visible, easier to coordinate, and able to share trust and results, we created the “All Consortium” co-creation network.

The All Consortium is not bound by capital ties; it is an open platform where members connect through shared goals and mechanisms. Each participant’s knowledge and experience is shared with all, forming the “Food Supply Web” that All solution envisions—a new horizontal ecosystem where every node supports the whole.

Four Benefits for Participants

①Performance becomes visible, accelerating inter-organizational collaboration.

Sales, purchasing, and staffing data are visualized so that trust and co-creation results are shared transparently. Talking through “the numbers” makes partnerships stronger and faster.

②Leverage know-how cultivated by peers.

Success stories and on-site innovations circulate openly among members; this cross-regional, cross-industry “knowledge hub” fuels further growth.

③Gain regional and social credibility through connection.

Being part of the Consortium signals a forward-looking stance that enhances reputation with local communities, government, education, and finance sectors.

④Grow your business network through barrier-free collaboration.

Connections are based on “purpose” and “system,” not capital stakes, making them flexible and sustainable—and enabling flat, open ties with partners from other regions and industries.

The Mechanism of Allsolution

Find job opportunities across ABURI Group and each business unit here.

Part-Time Staff

New Graduate Positions

Mid-Career Positions

Student / Hourly Jobs

We’re sharing Japan-based hiring updates—including new-graduate, mid-career, part-time, and hourly positions.